Serge Krush

Designing a Keg Lifecycle Tracking System

2021

Commercial Supply

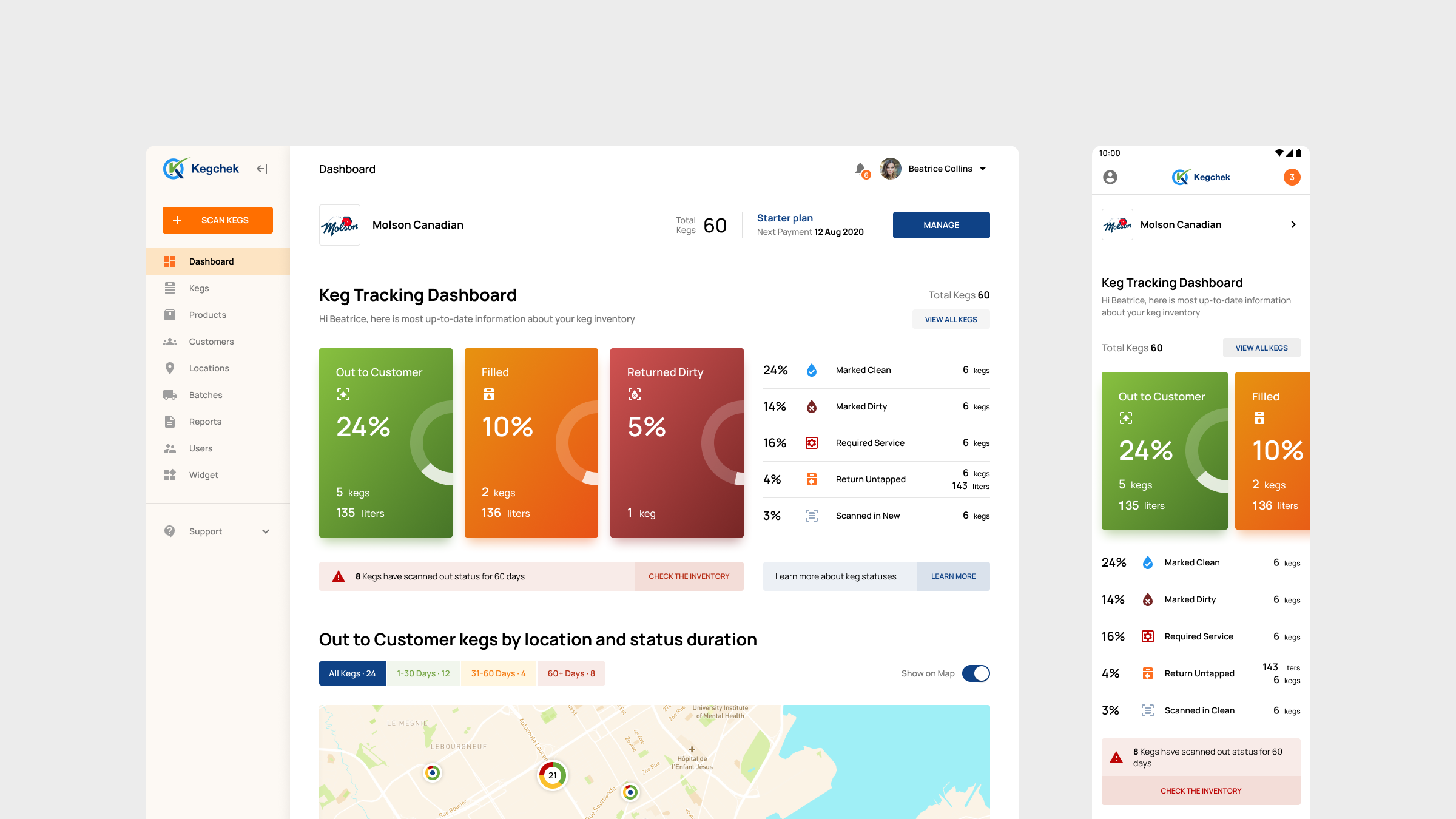

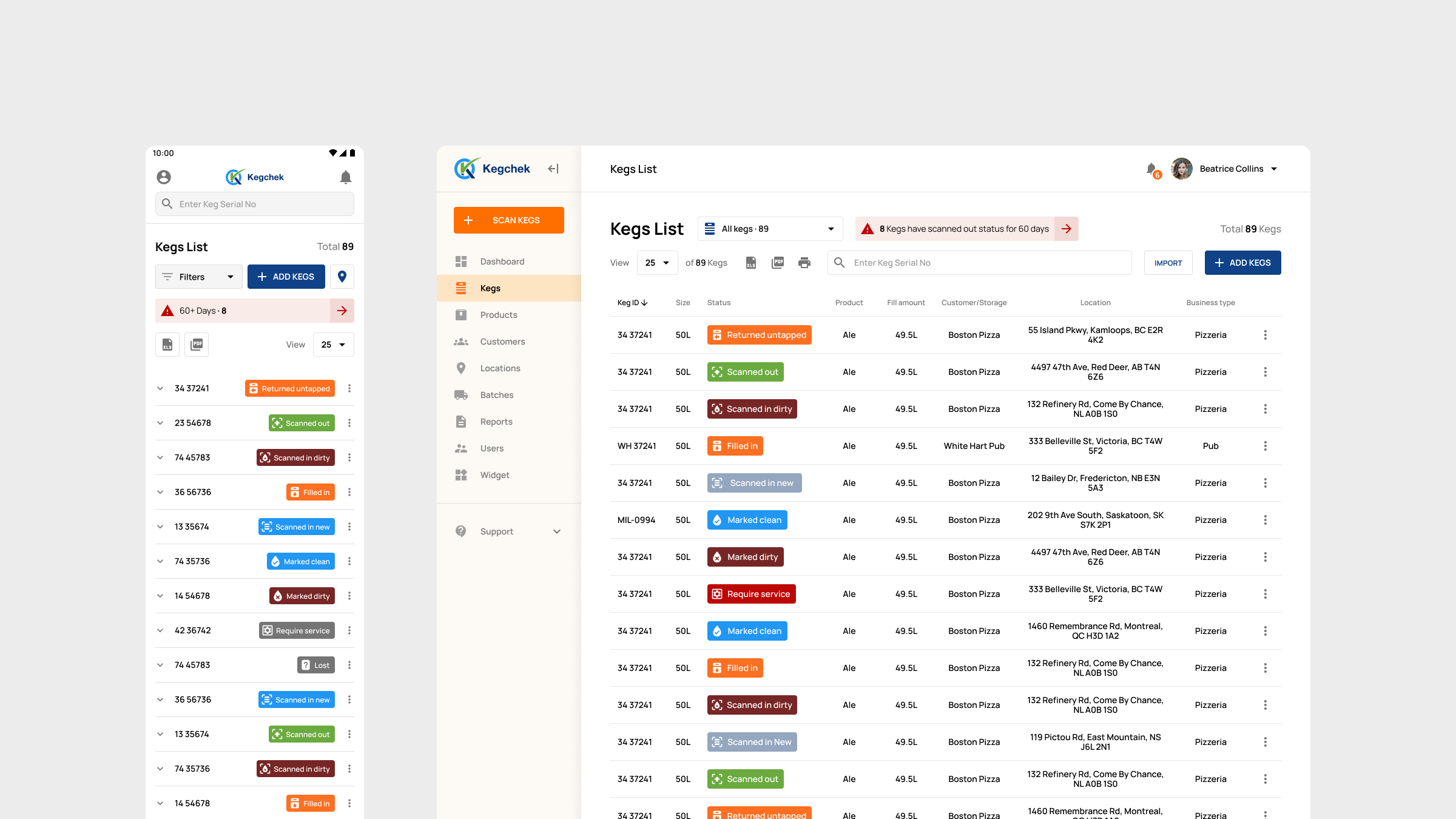

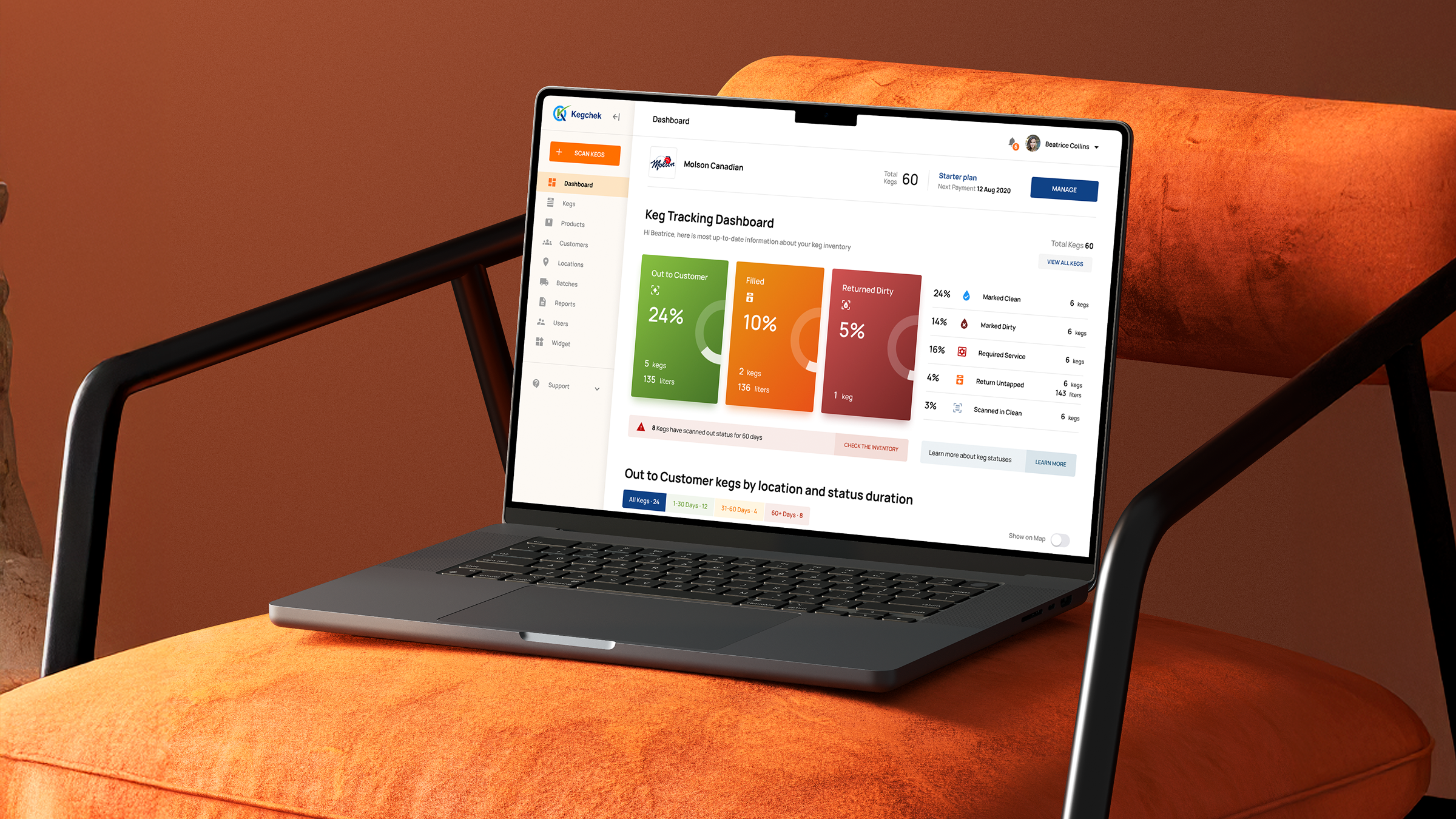

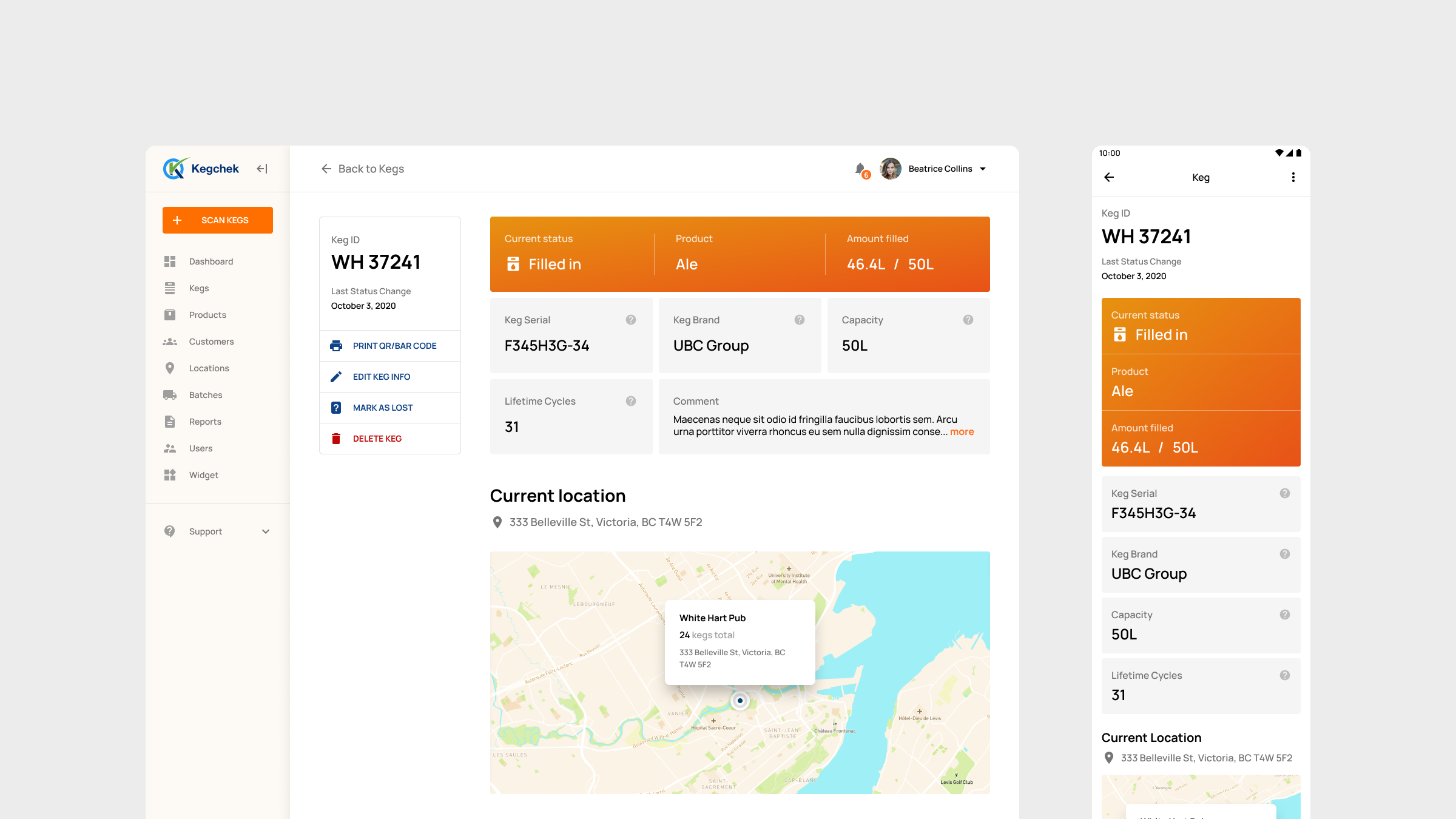

A keg tracking and management system for a keg manufacturer and its brewery clients, supporting asset tracking and maintenance scheduling through a subscription model

Problem Statement

Both the keg manufacturer and its brewery clients needed a unified system to track the lifecycle and status of leased and owned kegs, with fast identification in operational environments.

Solution Overview

The system was designed around barcode scanning and mobile-first workflows, developed in close collaboration with logistics and maintenance teams to ensure speed, accuracy, and ease of use in daily operations.

The system reduced the number of lost and misplaced kegs, improved maintenance scheduling accuracy, and enabled faster responses to unplanned operational changes

Design Process

The design process focused on building a practical, real-world asset tracking system informed by close collaboration with teams directly involved in keg production, logistics, maintenance, and warehouse operations. Decisions were driven by hands-on insights from people using the system daily.

01 Discovery & Domain Understanding

Understanding the full keg lifecycle — from manufacturing and leasing to delivery, usage, return, and maintenance. This phase aligned business goals with operational realities and technical constraints.

02 Cross-Functional Interviews

Conducting interviews with logistics, maintenance, manufacturing, and warehouse employees, as well as the technical team responsible for barcode scanning and hardware integration. These insights revealed critical workflows, pain points, and edge cases.

03 Workflow Mapping & Requirements Definition

Mapping real operational workflows and defining system requirements based on field observations and interview findings. This step ensured the system reflected how work actually happens, not idealized processes.

04 UX Strategy & Flow Design

Designing fast, low-friction user flows optimized for scanning, status updates, and exception handling. Special attention was given to speed, clarity, and usability in industrial and warehouse environments.

05 UI Design & Prototyping

Creating clear, durable interfaces for both desktop and mobile use, including camera-based scanning and dedicated scanner integration. Prototypes were tested against real scenarios to validate efficiency and accuracy.

06 Validation, Iteration & Delivery

Validating designs with operational teams, refining flows based on feedback, and preparing specifications for development. Iterative improvements ensured the system supported real-world usage and scaled with business needs.

Curious about what we could build together? 💬 Let’s talk.

Email me

Connect with me

Serge Krush

Cases

About

Resume

Designing a Keg Lifecycle Tracking System

2021

Commercial Supply

A keg tracking and management system for a keg manufacturer and its brewery clients, supporting asset tracking and maintenance scheduling through a subscription model

Problem Statement

Both the keg manufacturer and its brewery clients needed a unified system to track the lifecycle and status of leased and owned kegs, with fast identification in operational environments.

Solution Overview

The system was designed around barcode scanning and mobile-first workflows, developed in close collaboration with logistics and maintenance teams to ensure speed, accuracy, and ease of use in daily operations.

The system reduced the number of lost and misplaced kegs, improved maintenance scheduling accuracy, and enabled faster responses to unplanned operational changes

Design Process

The design process focused on building a practical, real-world asset tracking system informed by close collaboration with teams directly involved in keg production, logistics, maintenance, and warehouse operations. Decisions were driven by hands-on insights from people using the system daily.

01 Discovery & Domain Understanding

Understanding the full keg lifecycle — from manufacturing and leasing to delivery, usage, return, and maintenance. This phase aligned business goals with operational realities and technical constraints.

02 Cross-Functional Interviews

Conducting interviews with logistics, maintenance, manufacturing, and warehouse employees, as well as the technical team responsible for barcode scanning and hardware integration. These insights revealed critical workflows, pain points, and edge cases.

03 Workflow Mapping & Requirements Definition

Mapping real operational workflows and defining system requirements based on field observations and interview findings. This step ensured the system reflected how work actually happens, not idealized processes.

04 UX Strategy & Flow Design

Designing fast, low-friction user flows optimized for scanning, status updates, and exception handling. Special attention was given to speed, clarity, and usability in industrial and warehouse environments.

05 UI Design & Prototyping

Creating clear, durable interfaces for both desktop and mobile use, including camera-based scanning and dedicated scanner integration. Prototypes were tested against real scenarios to validate efficiency and accuracy.

06 Validation, Iteration & Delivery

Validating designs with operational teams, refining flows based on feedback, and preparing specifications for development. Iterative improvements ensured the system supported real-world usage and scaled with business needs.

Curious about what we could build together? 💬 Let’s talk.

Email me

Connect with me

Serge Krush

Cases

About

Resume

Designing a Keg Lifecycle Tracking System

2021

Commercial Supply

A keg tracking and management system for a keg manufacturer and its brewery clients, supporting asset tracking and maintenance scheduling through a subscription model

Problem Statement

Both the keg manufacturer and its brewery clients needed a unified system to track the lifecycle and status of leased and owned kegs, with fast identification in operational environments.

Solution Overview

The system was designed around barcode scanning and mobile-first workflows, developed in close collaboration with logistics and maintenance teams to ensure speed, accuracy, and ease of use in daily operations.

The system reduced the number of lost and misplaced kegs, improved maintenance scheduling accuracy, and enabled faster responses to unplanned operational changes

Design Process

The design process focused on building a practical, real-world asset tracking system informed by close collaboration with teams directly involved in keg production, logistics, maintenance, and warehouse operations. Decisions were driven by hands-on insights from people using the system daily.

01 Discovery & Domain Understanding

Understanding the full keg lifecycle — from manufacturing and leasing to delivery, usage, return, and maintenance. This phase aligned business goals with operational realities and technical constraints.

02 Cross-Functional Interviews

Conducting interviews with logistics, maintenance, manufacturing, and warehouse employees, as well as the technical team responsible for barcode scanning and hardware integration. These insights revealed critical workflows, pain points, and edge cases.

03 Workflow Mapping & Requirements Definition

Mapping real operational workflows and defining system requirements based on field observations and interview findings. This step ensured the system reflected how work actually happens, not idealized processes.

04 UX Strategy & Flow Design

Designing fast, low-friction user flows optimized for scanning, status updates, and exception handling. Special attention was given to speed, clarity, and usability in industrial and warehouse environments.

05 UI Design & Prototyping

Creating clear, durable interfaces for both desktop and mobile use, including camera-based scanning and dedicated scanner integration. Prototypes were tested against real scenarios to validate efficiency and accuracy.

06 Validation, Iteration & Delivery

Validating designs with operational teams, refining flows based on feedback, and preparing specifications for development. Iterative improvements ensured the system supported real-world usage and scaled with business needs.

Curious about what we could build together? 💬 Let’s talk.

Email me

Connect with me